The FDA’s designation for 503B outsourcing facilities has opened a fast-growing, high-demand segment in the compounding pharmacy market. There is tremendous potential to improve the purity and sterility of both human and veterinary drugs with the use of cGMP, or current Good Manufacturing Practices. While the FDA regulates adherence to the manufacturers’ quality, training, and control processes, pharmaceutical manufacturers must determine their own testing protocols and test equipment that make up cGMP.

Challenges in Measuring Ophthalmic Liquids

Ophthalmic liquids, or eye drops, are a top-selling 503B traditionally compounded medication used in both human and veterinary medicine. They present quality managers with unique liquid measurement challenges, including:

- Optical density

- Opacity

- Salinity

- Viscosity

- Capillary action

- Surface tension

Proper test and measurement protocols such as those used in 503B’s cGMP programs ensure that a medication meets quality standards for purity, potency, and sterility both batch to batch and bottle to bottle.

Effective Test Protocols

Consistency ensures a quality product, but 503B outsourcing is a capital-intensive undertaking. It’s important that quality managers and facility managers work together to select inspection systems that provide fast, scalable, and consistent non-contact test results.

503B manufacturers must design test protocols that are:

- Scalable from development to large volume production

- Flexible for on and offline testing, pre- and post-packaging

- User-friendly

- Able to provide reporting and documentation that meets the needs of company, FDA, and customer

One method to monitor for proper fluid composition is to measure its refractive index.

Non-Contact Testing with Refractive Index Measurement

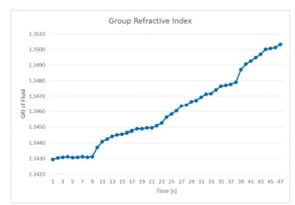

As shown in Figure 1, the refractive index determines how much the path of light is bent, or refracted, through a material. Figure 2 demonstrates that the interaction of light with the material can determine chemical consistency based on a control sample, an important control parameter for purity, potency, and sterility.

|

Figure 1. |

Figure 2. |

Accuracy, specifications, and more about the OptiGauge II |

To meet the testing needs for 503B manufacturers, Lumetrics has developed a method to monitor the temperature and calculate the measured group refractive index of a fluid by measuring changes in its refractive index using a low-coherence interferometer, the OptiGauge II. Combined with custom software, the group refractive indices of fluids can be quickly and accurately measured, on or offline. The OptiGauge II non-contact measurement system is proven to measure flowing liquid as well as bottled ophthalmic liquid.

This approach can be adapted for online applications to monitor the temperature and concentration of fluids in real-time and in a completely non-invasive manner.

Learn more about how non-contact testing and the refractive index may support your test protocols for ophthalmic liquid and other oral medications, talk with our engineers.

More Resources:

How is group refractive index (GRI) measurement used in testing medical grade fluids? View the test data and more in the app notes: